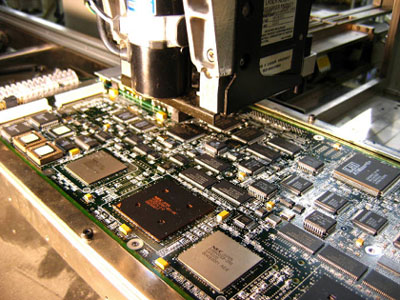

Specializing in circuit board assembly for Military, Medical, Instrumentation and Industrial Equipment Industries.

DUNS: 603156399 CAGE Code: 441M8 NAICS: 334418

CORE COMPETENCY Capabilities

Capabilities

CORE Capabilities:

- Through Hole PCB Assembly

- Surface Mount Technology

- Single and Double Sided to 0201

- RoHS and Leaded Manufacturing

- Aqueous and No-Clean Processes

- Conformal Coating

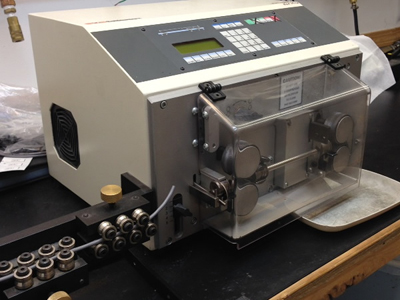

- Cable and Harness Assembly

- Prototype to Full Production Runs

- Low-Medium Volume, High Mix Products

- Engineering Rework and Modifications

- Board Assembly Repair

- Functional Testing

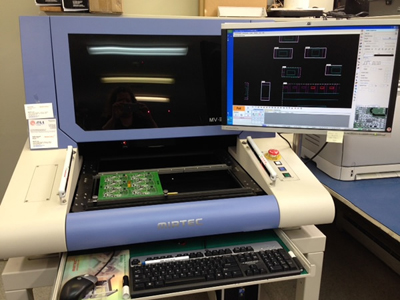

- Automatic Optical Inspection Testing

- Kit Supplied or Turnkey

- Integrated Box-Build Systems

- IPC610B, J-Standard, Mil Spec Quality Assurance

- In Line with ISO9000

- Certified IPC Trained Personnel

- ESD Compliant

- ESSEMTEC FLX2010 Pick and Place

- Mirtec MV-3L AOI

- Manncorp SMT CR.5000F Reflow Oven

- 18" Electrovert Wave Solder System

- Aqueous Cleaning System

- Pre-Bake Ovens

- SMT Rework and Desoldering Stations

- Temperature Controlled Soldering Stations

- GPS Lead Forming Equipment

- Microchip Programmer

"What we do, what we use, who we do it for, why we do it."

Let us put our expertise to work for you.

Let us put our expertise to work for you.

At Core Assemblies, we understand that it takes a combination of the right people and the right equipment to do the right job. A skilled technician proficient with the right tool is the formula for maintaining consistent high quality production.

IPC Certified Trainer In-house

We utilize IPC 610 B class 2 and class 3 as our quality standard. We know that your reputation and your business are on the line with every order you place with us.

Feel free to contact us concerning your circuit board assembly requirements, surface mount or through hole, rework to the latest engineering drawings, cable assemblies, mechanical assemblies, kitted or turnkey.

Core Assemblies will help you every step of the way.

Let us put our expertise to work for you.

Let us put our expertise to work for you.